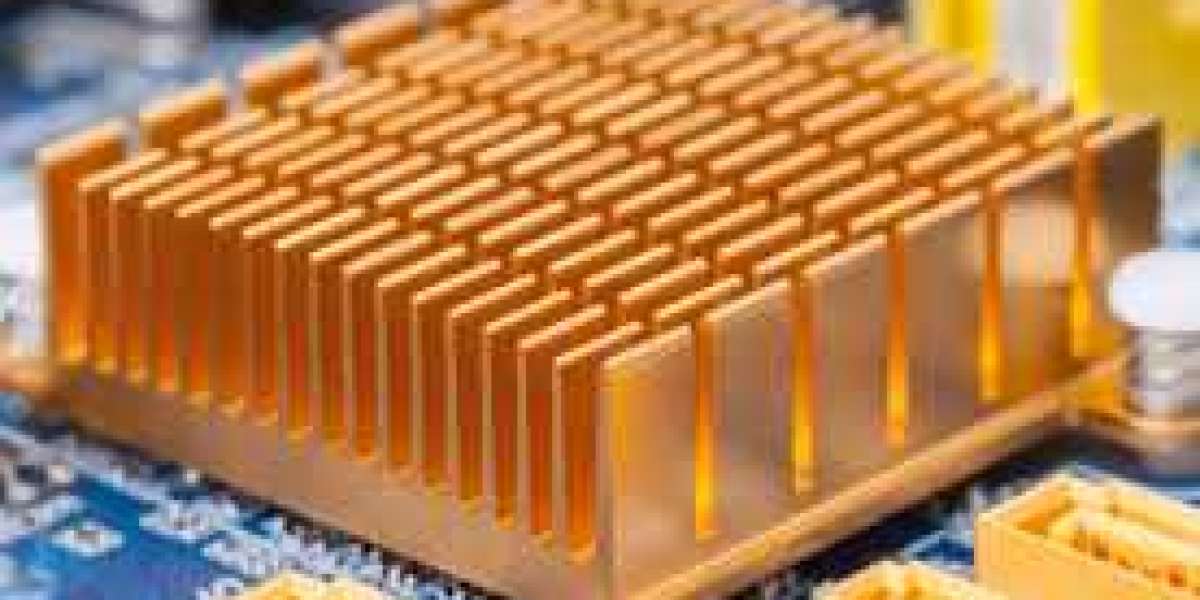

sustainability is a key concern across various industries, including thermal management. One critical component that plays a vital role in managing heat dissipation in modern applications is the Custom Die Cast Heatsink. These heatsinks, designed for specific needs, not only provide superior thermal performance but also have significant environmental implications. Understanding how Custom Die Cast Heatsinks impact the environment is crucial for making informed decisions about their use in industries such as electronics, automotive, and renewable energy.

1. Energy Efficiency and Heat Management

A primary benefit of Custom Die Cast Heatsinks is their ability to enhance the energy efficiency of devices. By effectively dissipating heat, they help prevent overheating, which can lead to energy loss and reduced performance. Efficient cooling ensures that devices operate at their optimal temperature, reducing energy consumption. As energy-efficient systems require less power to operate, the environmental impact is minimized by lowering the demand for energy resources.

2. Material Selection and Recyclability

The environmental impact of Custom Die Cast Heatsinks largely depends on the materials used in their production. Many custom heatsinks are made from metals such as aluminum, which is highly recyclable. By using recyclable materials, manufacturers can reduce the environmental footprint of heatsinks over their entire lifecycle. The ability to recycle custom die cast heatsinks at the end of their life reduces waste and contributes to a circular economy.

3. Reducing Waste in Manufacturing

The die casting process used to create Custom Die Cast Heatsinks is known for its precision and minimal waste production. Compared to traditional manufacturing methods, die casting generates fewer byproducts, which means less material waste. This reduction in scrap metal helps conserve resources and reduces the environmental burden of producing heatsinks. Furthermore, the high durability and long lifespan of custom die cast heatsinks mean that they are less likely to require frequent replacements, which further reduces waste.

4. Supporting Green Technologies

The use of Custom Die Cast Heatsinks extends beyond traditional applications and is also crucial in green technologies, such as electric vehicles (EVs) and renewable energy systems. In these industries, efficient thermal management is essential for optimizing performance and energy conservation. By integrating custom die cast heatsinks into electric vehicles or solar power systems, manufacturers can contribute to more sustainable and eco-friendly solutions.

Custom Die Cast Heatsinks offer several environmental benefits, from enhancing energy efficiency to supporting sustainable manufacturing practices. By utilizing recyclable materials and reducing waste during production, they help minimize their environmental footprint. As industries continue to prioritize sustainability, the role of Custom Die Cast Heatsinks in promoting greener technologies and energy conservation will only become more significant.