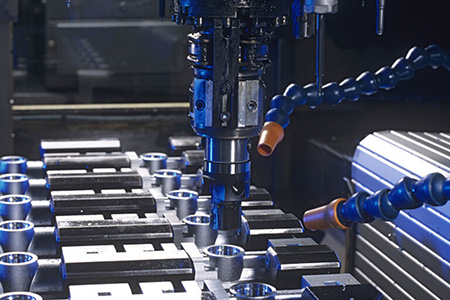

One of the most important connections in the manufacturing sector is that which exists between computer numerical control (CNC) cnc machining service and direct metal laser sintering (DMLS), which is the most advanced technology for the 3D printing of complex metal parts.

The latter technique can produce components in virtually any shape by utilizing laser beams and heaps of metal powder, but the process can be time-consuming at times

Components can be produced using this technique

Machining, on the other hand, offers a reduced number of geometric possibilities, but it can speed up the rate at which production rates are increased

Therefore, the selection of which to use is primarily determined by two factors: a) the quantity of components that need to be manufactured, and b) whether or not one or more of the components can be machined

The two distinct strategies for manufacturing are able to, in many instances, complement one another as production methods. In what ways does this idea find expression in real life? In metal-based additive manufacturing, the process that typically makes use of subtractive manufacturing, which is the opposite of additive manufacturing, is the norm. Holes need to be drilled, carved, threaded, or milled, and critical surfaces need to be milled, turned, or ground to the appropriate dimensions. Other processes may also be required. Before 3D-printed parts can be taken to a machine shop for further processing, they are required to undergo a bare minimum of three processes: sandblasting, the removal of brackets, and manual TLC cleaning.

What do people who are looking for the most time- and cost-effective methods to make functional prototypes and a limited quantity of metal parts for final use need to know about this information? To a very great extent. If you adopt a strategy that enables metal printing and 3D online cnc machining service to be different steps in the same manufacturing process, you will be able to take advantage of the benefits that are associated with both of these processes. The elimination of surprises, a reduction in costs, and an improvement in part design are all possible outcomes of doing so. You should give some thought to the design considerations that are provided in the following paragraphs before moving on to designing metal parts for your next project. These paragraphs are provided for your convenience.

Fabrication of metal components, in addition to cutting and forming

As was mentioned at the beginning of this piece of design advice, it is crucial to exercise a high degree of control over the process that is used to make them. This is because it is essential to make sure that they are made correctly. DMLS is the only additive manufacturing technology that can print metal, and Protolabs uses a total of five different kinds of these technologies for their manufacturing processes. In the same manner as any other powder bed printing process, this one uses a laser (or multiple lasers) to sinter metal powder particles the size of flour into a cavity that has been constructed within the machine. This is done in the same manner as any other powder bed printing process. The machine melts a thin layer of the paper-like work one at a time, and after each pass, the coating blade drags fresh powder to the top. This process continues until the work is completed. The process of melting starts at the bottom and works its way all the way up to the top.

Machine cutting, on the other hand, makes use of extremely long-lasting cutting tools to remove metal. This can be accomplished in one of two ways: either by moving a stationary tool in opposition to a piece that is being rotated (a method known as turning), or by milling, which involves rotating the tool in opposition to a piece that is being held still. The processing includes a number of additional explanations on a microscopic level, but for the time being, it is essential to comprehend that the processing starts off exactly where the DMLS left off. To phrase it another way, DMLS is the process of adding material in a single layer. Machining requires the removal of material, sometimes in very large quantities and other times in only very small amounts, in order to produce a surface finish that is satisfactory to the customer.

Taking into consideration the impeccable precision of the metal components

The Direct Metal Laser Sintering (DMLS) technique enables the creation of extremely complex shapes that would not be possible to manufacture using traditional methods; however, this technique does not liberate manufacturing from all of its limitations. First, as the laser completes its work, it performs significant heating and cooling on the metal. This creates internal stresses that need to be eliminated by post-construction heat treatment, and it does so by performing these actions. Heating the metal to a specific temperature is the only method that is capable of removing these stresses. This does not mean very much to the person who is designing the part; the only thing that it does mean is that the elimination of stress is equivalent to a certain amount of motion of the part, which indicates that there will be a certain loss of accuracy. Other than that, this does not mean very much. This is one of the reasons, but certainly not the only reason, why even a well-designed part and DMLS production require online cnc machining service any part with poor characteristics or tolerances. However, this is the only reason that applies to poor characteristics or tolerances. Having said that, this is one of the primary explanations.